Thiolated Polymers for 3D-Bioprinting

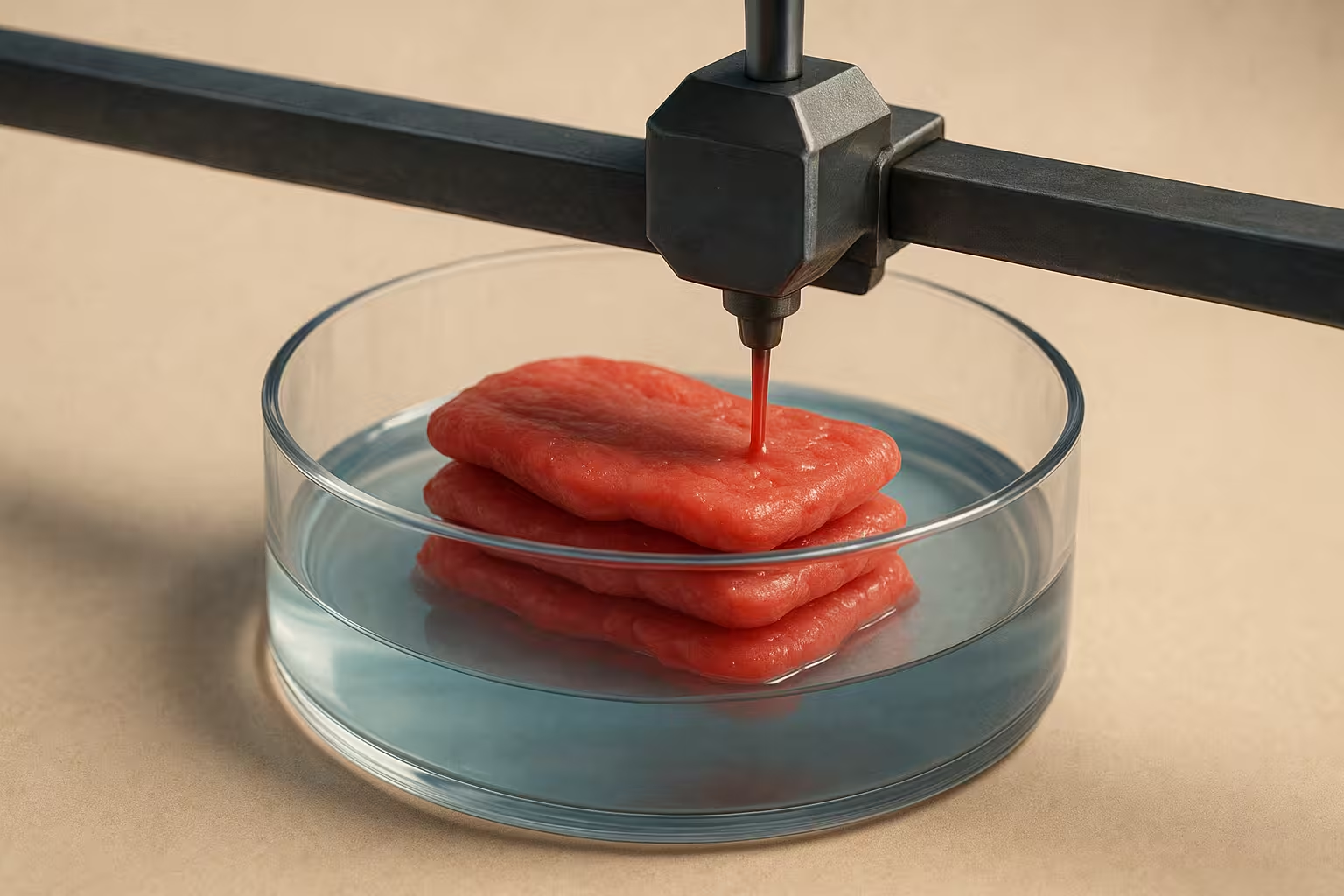

Bioprinting is an advanced form of additive manufacturing that involves the layer-by-layer deposition of bioinks—materials composed of living cells and biocompatible scaffolds—to create complex biological structures, such as tissues and organs. This technology holds great promise in regenerative medicine, drug testing, tissue engineering, and the development of patient-specific implants. The main goal of bioprinting is to fabricate functional tissue constructs that mimic the architecture and function of native tissues, potentially solving organ donor shortages and improving personalized healthcare.

A critical component in bioprinting is the choice of bioink. Bioinks must support cell viability, proliferation, and differentiation while also possessing suitable mechanical properties and printability. Hydrogels are commonly used as bioinks due to their high water content and similarity to the natural extracellular matrix (ECM). Among them, thiolated polymers are gaining attention due to their enhanced crosslinking capabilities and tunable properties.

Thiolated polymers, also known as thiomers, are polymers functionalized with thiol (-SH) groups. These functional groups allow for covalent bonding through disulfide bridges or Michael-type additions with maleimide or acrylate compounds. This chemical reactivity makes thiolated polymers particularly useful in bioprinting, as they enable rapid and stable gelation under physiological conditions. These polymers can be natural (e.g., thiolated hyaluronic acid, gelatin) or synthetic (e.g., thiolated polyethylene glycol or PEG), offering flexibility in design and application.

One of the key advantages of thiolated polymers in bioprinting is their ability to form hydrogels with tailored mechanical strength, degradation rate, and bioactivity. The crosslinking density can be adjusted to match the mechanical needs of different tissues or control the release of encapsulated drugs or growth factors. Additionally, the mild and cytocompatible crosslinking process ensures high cell viability during and after printing.

Thiolated polymers also offer the potential for dynamic and stimuli-responsive behavior. For instance, disulfide bonds can be reversible, enabling hydrogels to degrade in response to redox conditions—an important feature for controlled drug delivery or tissue remodeling.

In summary, bioprinting is revolutionizing biomedical engineering, with thiolated polymers playing a crucial role in advancing the field. Their unique chemical properties enable the fabrication of customizable, biocompatible scaffolds that support complex tissue structures. As research continues, the combination of bioprinting techniques with thiolated polymers is expected to drive significant progress in tissue regeneration, personalized medicine, and biofabrication.

References

- Le-Vinh B, Steinbring C, Nguyen Le NM, Matuszczak B, Bernkop-Schnürch A. S-Protected Thiolated Chitosan versus Thiolated Chitosan as Cell Adhesive Biomaterials for Tissue Engineering. ACS Appl Mater Interfaces. 2023 Aug 30;15(34):40304-40316. doi: 10.1021/acsami.3c09337

- Summonte S, Racaniello GF, Lopedota A, Denora N, Bernkop-Schnürch A. Thiolated polymeric hydrogels for biomedical application: Cross-linking mechanisms. J Control Release. 2021 Feb 10;330:470-482. doi: 10.1016/j.jconrel.2020.12.037

- Asim MH, Silberhumer S, Shahzadi I, Jalil A, Matuszczak B, Bernkop-Schnürch A. S-protected thiolated hyaluronic acid: In-situ crosslinking hydrogels for 3D cell culture scaffold. Carbohydr Polym. 2020 Jun 1;237:116092. doi: 10.1016/j.carbpol.2020.116092

- Leichner C, Jelkmann M, Bernkop-Schnürch A. Thiolated polymers: Bioinspired polymers utilizing one of the most important bridging structures in nature. Adv Drug Deliv Rev. 2019 Nov-Dec;151-152:191-221. doi: 10.1016/j.addr.2019.04.007